“Security Measures Make Vacuum Tube Collector Systems More Expensive”

Marek Szymanski, technical department manager of the Polish collector manufacturer Watt, spoke with solarthermalworld.org about the problems they had with the vacuum tube collectors in the beginning. Photo: Watt

Marek Szymanski, technical department manager of the Polish collector manufacturer Watt, spoke with solarthermalworld.org about the problems they had with the vacuum tube collectors in the beginning. Photo: Watt

Vacuum tube collectors are gaining importance on the solar thermal market in Poland. The company Watt was one of the first Polish system suppliers to integrate vacuum tubes into their portfolio, actually as early as 2003. Watt purchases double-glass Sydney tubes from China and combines them with a U-pipe absorber at the factory in Silesia, Poland. Marek Szymanski, technical department manager of Watt, made the following statement concerning his experiences with vacuum tube technology.

“We encountered several problems with the vacuum tube collectors in the beginning – mostly because installers did not handle them properly. In one case, the plumber left the delivered collector modules for two weeks in bright sunshine. The stagnation temperature reached 800 °C and the copper pipes melted and became useless. Other installers burned out themselves while working on the roof, because they were not aware of the fact that collectors in stagnation can reach extremely high temperatures.

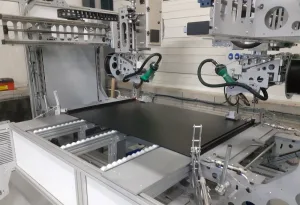

Providing stagnation temperatures during installation: a polystyrene form that covers the entire tube area. Photo: Watt

Providing stagnation temperatures during installation: a polystyrene form that covers the entire tube area. Photo: Watt

We therefore had to consider security measures. So, today we deliver all our collectors under a polystyrene form that covers the entire tube area. “Do not unwrap until joined to the heating system!” is the important rule.

We furthermore implemented some additional measures to guarantee a secure and correct operation of the vacuum tube collectors. Unfortunately, these measures drive up the price as well:

- To prevent steam at high temperatures from reaching the solar station, the pumps and the valves in the cellar, we recommend an expansion vessel that is six times bigger than with a flat collector.

- An additional check after filling ensures that the solar circuit is free of air bubbles, because U-pipe collectors are much more difficult to vent. Furthermore, air bubbles can stop the flow in the U-pipe and decrease efficiency.

- An automatic pump increases the pressure in the circuit to 5 bar, so that leakages will be spotted and air bubbles removed. Sydney tube collectors are much more difficult to vent due to the construction of the collector. Additionally, air bubbles can have a negative effect on the u-tube, which will not work when being left in that condition. Nothing will be able to flow through and, hence, there will be no heat exchange: the result will be an overheating of the tube itself. Another emerging difficulty besides the aforementioned can be “hot spots” that will occur if vacuum collector have not been correctly vented. The temperature sensor may show error readings in some particular cases of operation.

- We use a glycol that is specifically adapted to vacuum tube collectors.

If one adheres to these security measures, vacuum tube systems will perform well. Today, more than half of our collector area is sold with this kind of technology.”

Statement of Marek Szymanski, technical department manager of the Polish collector manufacturer Watt Ltd.