Europe: Solar Keymark Network to Improve Complaint Procedures

March 31, 2016

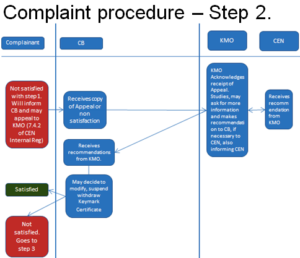

The Solar Keymark Network has decided to establish a working group in order to revise and improve the complaint procedures and put them into one document, as they have so far been described in several different papers and various articles: The Solar Keymark Scheme Rules, Article 2.2, includes instructions on how to handle complaints and there is Article 6.3. Special Test, whereas the CEN-CENELEC Internal Regulations Part 4, Article 7.4, describes the appeal procedures (see the attached documents). This move is deemed necessary because at the end of 2015 – for the first time since the Solar Keymark label was launched – several complaints were submitted to one of the empowered certification bodies. “In our network meeting, we informed the members about the first big complaint and discussed the need for putting the complaint procedures into one document, to make it clearer for the solar thermal industry how to use them,” said Jaime Fernández González-Granda, Chairman of the Solar Keymark Network and Product Officer at the Spanish certification and standardisation body, AENOR.

Starting point of the complaint series was summer 2015, when Stefan Abrecht, General Manager of German company Solar Experience, noted some problematic test results on Arcon collector certificates issued by the Swedish test laboratory and certification body SP in October 2014. Abrecht informed both Danish manufacturer Arcon-Sunmark and SP about his observations. Three months later in November 2015, SP asked the Keymark Secretariat to remove the four certificates from 31 October 2014 and to upload new versions of the certificates issued on 11 November 2015 (see the following table).

| Collector type |

HTHEAT |

HTHEAT |

HTHEAT |

HTHEAT |

| Foil |

No |

No |

Yes |

Yes |

| Licence No. |

SP SC0840-14 |

SP SC0841-14 |

SP SC0842-14 |

SP SC0843-14 |

| eta_0 |

0.859 |

0.851 |

0.838 |

0.808 |

| c1 in W/m²K |

2.391 |

2.753 |

1.865 |

1.353 |

| c2 in W/m²K² |

0.029 |

0.016 |

0.018 |

0.022 |

Four Arcon certificates issued by Swedish test institute SP on 11 November 2015. The performance coefficients eta_0, c1 and c2 all relate to the aperture area.

Source: Solar Keymark certificates

Source: Solar Keymark certificates

Six complaints submitted to Swedish certification body

Several solar thermal industry professionals and test laboratories considered some of the c1 and c2 values implausible and used the instructions of Article 2.2, Handling Complaints on Bodies Engaged in Testing and Inspection. The procedures say that complaints are to be submitted to the involved certification body, which will forward them to the relevant test laboratories. In the case of SP, the certification body and the test lab are separate and independent departments in the same institute. SP certification received six complaints, issued by two collector manufacturers (KBB from Germany and Tisun from Austria), two German research institutions (ITW – Institute of Thermodynamics and Thermal Process Engineering and ISFH – Institute for Solar Energy Research Hamelin), the Austrian solar industry association Austria Solar and Austrian installation company Mysolar.

In brief, the experts criticised that the heat loss coefficients c1 were too low and together with the unusual high c2 values, they led to an overvalued collector yield at 50 °C. “The aim of Solar Keymark is to harmonise and assure the quality of solar thermal products and their norm-based test results across the EU. This is to ensure that every product undergoes a fair comparison based on accurate test results. From our point of view, the certificate in question issued by SP does not meet this criterion,” Carsten Lampe, head of the test lab at ISFH, explained his motivation behind filing the complaint. “According to the solar yields in the certificates, the Arcon collectors produce 6.5 % more kilowatt-hours per year, although our collectors are at least at the same level,” emphasised Robert Kanduth, Managing Director of Austrian collector manufacturer Greenonetec. He did not file a complaint because Greenonetec and Arcon had belonged to the same company group, Solarcap, some years ago.

Retest to be confirmed by a third party expert

“After receiving the complaints about certification issues regarding one of our clients, SP initiated a process to have these results re-checked and validated through a second performance test, and an action plan was set up and communicated to the complainants and to the Solar Keymark secretariat,” Staffan Ljung, Media Relations Manager at SP, told solarthermalworld.org on 29 February. The outdoor tests have been scheduled for mid-March to mid-April. “To ensure reliable and transparent tests, a third-party expert, appointed by SP in accordance with the information exchange between SP and the SKN secretariat, monitors the test sequence and evaluation of the test and test data,” Ljung added. Arcon-Sunmark supports the view that agreed regulations and procedures are to be followed 100%. “If a test was suspected of being inaccurate, this test must be validated as soon as possible,” confirmed Søren Elisiussen, CEO of Arcon-Sunmark. ”This specific test is carried out by a third party accredited test institute and we have no influence on the outcome of it, but we are fully confident that SKN and SP will do their utmost to resolve the issue.”

Solar yield tolerances of 10 % are distortion of competition

The organisations filing the complaints were not entirely satisfied with the above-mentioned proposals, as discussed at the Solar Keymark meeting in Berlin at the beginning of March. They criticised that SP was not willing to publish the measuring data of the existing certificates, so that the results could be debated and analysed by other experts. Some stakeholders also claimed that it would have been better to ask a third-party test lab to carry out retesting. The third important point referred to the regulation that special retesting would allow solar yield tolerances of up to around 10 % below or above the original result. Article 6.3.1 of the Solar Keymark Scheme Rules says: “The integral of the measured instantaneous efficiency at the special test shall be more than 90 % of the already registered integral.” “We do not consider a 10 % tolerance in test results an acceptable outcome, but simply a distortion of competition; the tenders that Arcon won could have never been won by any other market player at possible system performance variations of up to 10 %,” Robin Welling, Managing Director of Tisun, explained his view.

This is an especially delicate issue, considering that a project for a 150,000 m² solar district heating plant in the Danish municipality of Silkeborg was decided in February 2016 after the complaints had already been filed and Arcon still won the tender.

“The 10 % rule will indeed be an important part of the work carried out by the newly founded working group,” confirmed SKN Chairman Fernández González-Granda. “Of course, this will require some careful analysis by the experts in the field.” The working group will start on the basis of the draft document for a new and comprehensive complaint procedure, which was presented at the SKN meeting in Berlin, and it will discuss the various comments and concerns raised during the meeting.

Websites of companies and institutions mentioned in the article:

Solar Keymark Network: http://www.estif.org/solarkeymark/network.php

AENOR: http://www.aenor.es

Tisun: http://www.tisun.com/home/

Greenonetec: http://www.greenonetec.com/en/

Austria Solar: http://www.solarwaerme.at/ (in German)

SP: http://www.sp.se

Mysolar: http://www.mysolar.at/ (in German)

Arcon-Solar: http://www.arcon-sunmark.com