Homeowners and businesses in Cyprus showed growing interest in solar thermal technology over the last two years. Collector area additions on the island increased by 5 % in 2018 and […]

India’s first-ever commercial concentrating solar thermal plant, which consists of parabolic trough collectors made by German supplier Protarget, has been running successfully at a dairy owned by Hatsun Agro Products. […]

UAE-based Ocean Rubber Factory has been satisfied with its new 240 m² solar process heat system made by Swiss supplier TVP Solar. Mounted on the company’s factory roof in the […]

Four weeks ago, Belgian technology supplier Sunoptimo started up a solar thermal turnkey system at Lys Services, a tank cleaning company based in Merville, in northern France. The hydraulic components […]

In June, Al Bashir Hospital, the largest public hospital in Jordan, started up a 1,133 m² (0.8 MWth) solar field which it said would provide 10 % of the heat […]

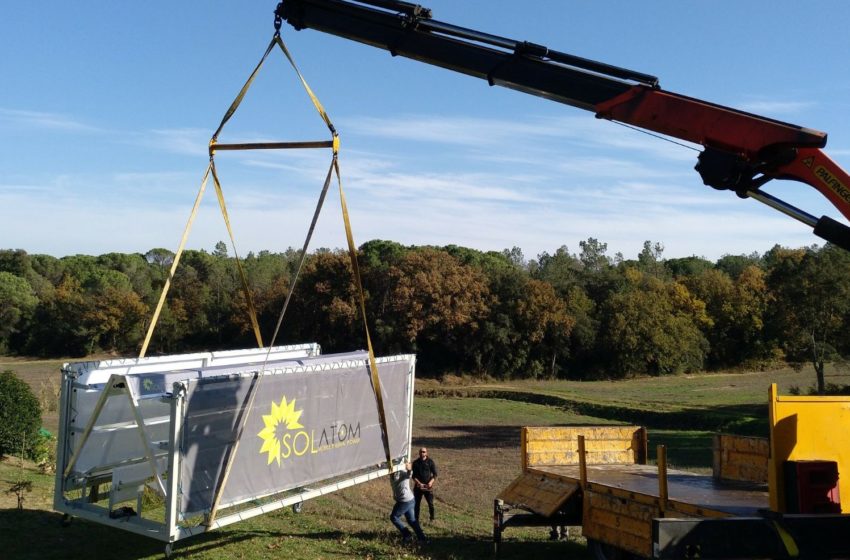

Despite great untapped potential, the Spanish solar process heat market is not growing as expected. Is it perhaps because many in the industry are not targeting the right sort of […]

Operators of several gas-driven combined cycle power plants, or CCPPs, have notified the German Federal Network Agency of their systems’ final shutdown. These plants are no longer economically viable, as […]

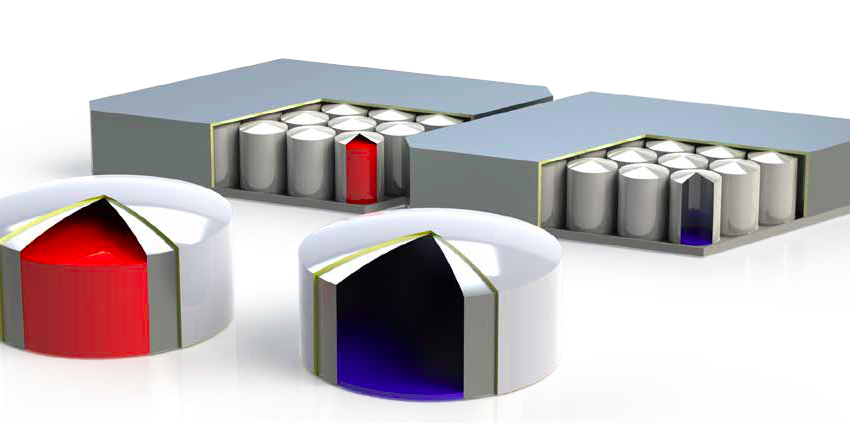

Cost-effective energy storage is key to transitioning to a low-carbon society. Energy can be stored in the form of heat or electricity. A popular storage method for high-temperature thermal applications […]

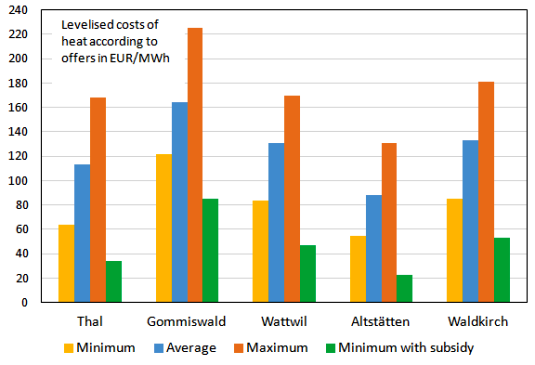

“Why is there no solar district heating in Switzerland?” Swiss scientists were asking after their visit to Denmark. They had been investigating the feasibility of solar heat in district heating […]

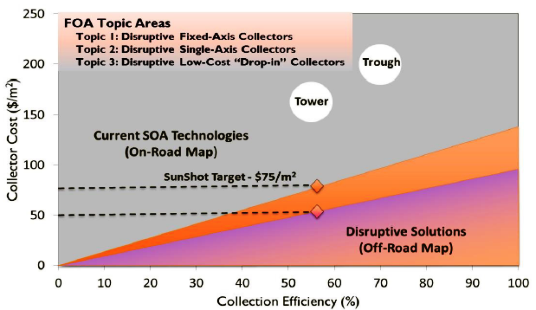

A tender for 94.5 USD/MWhel in Dubai and an R&D initiative called SunShot in the United States have shown how the cost of concentrated solar power (CSP) could be lowered […]