Parabolic trough collector production line shipped to China

Absolicon, a Swedish supplier of concentrating solar thermal technology, has recently delivered its first production line to a Chinese company. The equipment to manufacture parabolic trough collectors, which the Swedish business developed in-house, arrived in China in mid-April. The line is now being set up at Heli New Energy Technology, in the country’s southwestern province of Sichuan. The photo, which dates from December 2016, shows the partners involved in the project after they signed the purchase agreement for the system. Heli New Energy is a joint venture between two Chinese companies, namely Xinkun, a family-owned manufacturer, and Jointeam, an energy project developer.

Photo: Absolicon

As part of the joint venture, Xinkun will be responsible for producing the collectors and managing logistics, while Jointeam will be in charge of sales and project development. “We will assist our Chinese customers in scaling up production and engineering initial projects,” Joakim Byström, CEO of Absolicon, said. The deal comes at a time when the Chinese government has established the ambitious target of generating 10 % of industrial heat via solar thermal energy by 2020.

One collector every 6 minutes

“Our business idea is to offer interested companies from around the world complete production lines, including robots, that provide a yearly capacity of around 100,000 m² of glazed parabolic trough collectors, type T160,” Byström (third from left) said. The sales contract with Heli New Energy was valued at around EUR 2.5 million and included 400 m² of prefabricated solar collector area for use in demonstration plants.

Byström is planning to put the money generated from these sales into the construction of a completely automated and enhanced collector production line at Absolicon’s headquarters in Härnösand, Sweden. “It will enable us to manufacture one 5.5 m² T160 every 6 minutes. The installation will be a showcase for new customers who are interested in purchasing a T160 production line,” the CEO explained. “Outside Europe, we have started looking for manufacturing partners in Botswana, Chile, Egypt, India, Kenya, Mexico, Morocco and South Africa.”

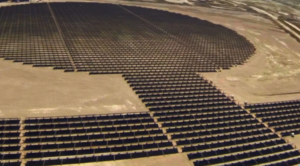

A 270 m² solar district heating plant commissioned for installation in Sollefteå, Sweden, in 2012

Photo: Absolicon

The T160 collector has seen continuous improvements in performance and costs over several years. The parabolic trough system is covered by 4 mm of hardened glass to protect the mirror from dust and soiling. The receiver is also beneath a glass cover, which removes the need for evacuating it to attain good thermal performance. The collector is installed in sets of four modules. They have an aperture area of 22 m² each and share a control system to cut costs.

The T160 has been designed for district heating and industrial heat systems operating at temperatures of up to 160 °C. Collector tests at the laboratory of the Swiss-based SPF – Institute of Solar Technology last summer showed a 76.6 % optical efficiency. The manufacturer said that the good value had been the result of several improvements. Not only had the optical shape been optimised, but the reflectance of the mirror had been increased to 95.5 %, while the tracking accuracy had been fine-tuned to 0.1°. The company expects the Solar Keymark certificate to arrive this June.

Organisations mentioned in this article: