IEA SHC Solar Academy: Record Participation in Solar Heat for Industry Webinar

July 21, 2017 With more than 500 registered participants from 78 countries, Solar Heating for Industrial Processes has been the most frequented webinar of this year’s series hosted by the International Solar Energy Society, proving that there is great interest in this solar thermal application among planners, collector manufacturers and research institutions. This second IEA SHC Solar Academy webinar had researchers present reports and useful tools based on the work of IEA Solar Heating and Cooling Programme Task 49, Solar Heat Integration in Industrial Processes (2012 to 2015). A recording of the event is available online.

With more than 500 registered participants from 78 countries, Solar Heating for Industrial Processes has been the most frequented webinar of this year’s series hosted by the International Solar Energy Society, proving that there is great interest in this solar thermal application among planners, collector manufacturers and research institutions. This second IEA SHC Solar Academy webinar had researchers present reports and useful tools based on the work of IEA Solar Heating and Cooling Programme Task 49, Solar Heat Integration in Industrial Processes (2012 to 2015). A recording of the event is available online.The most visible outcome of Task 49 is certainly the online database SHIP-plants.info, which lists 253 finished installations totalling 194,343 m² (111 MWth). The database can be searched by country, application, solar supplier, collector technology, etc. However, the list of publications from Task 49 is much longer.

Another online database was presented by Task 49 coordinator Christoph Brunner from Austrian research institute AEE INTEC. The Wiki Web’s Energy Efficiency Finder includes a table showing the most important industrial sectors for solar process heat: automotive, chemicals, food, leather, metal and textiles. There are solar integration designs available for most major production processes, and parameters are listed for several industrial sectors. Brunner explained: “The Efficiency Finder offers a practical overview to engineers and planners who haven’t yet familiarised themselves with the industrial-scale production of the technology.”

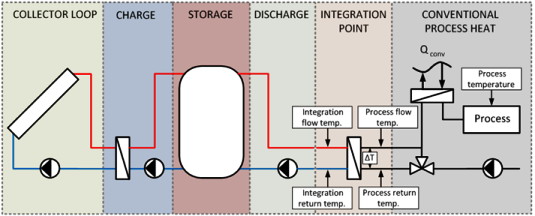

The designs and parameters have been taken from the so-called Integration Guidelines (see the attached document). Solar heat can be provided at different integration points, which has resulted in two distinct designs: On the supply level, this means either solar heat preheats a storage tank or steam is fed into a factory steam network. However, heat can also be fed directly into the process loop (process level). Although collector efficiency is usually lower at the supply stage, those approaches require fewer details and can more easily incorporate changes made to processes later, as shown in the table by Pedro Horta, Head of the Solar Process Heat and Industrial Systems group at Fraunhofer ISE, Germany (see below).

|

|

Process level |

Supply level |

|

Detailed process data |

Required |

Not needed |

|

Preliminary analysis of process integration |

Essential |

Generally recommended |

|

Flexibility to accommodate changes in processes |

Low |

High |

|

Collector efficiency |

Potentially higher |

Usually lower |

|

Solar heat contribution potential |

Restricted |

Usually higher |

|

Heat storage |

Depends on profile of selected process stream(s) |

Not necessary if not exceeding utility base load |

Benefits and drawbacks of typical integration concepts

Source: Fraunhofer ISE

Tough challenges ahead

The webinar speakers agreed that there was great momentum for SHIP. But they also addressed several technical and market challenges which need to be tackled to break the vicious circle of low deployment rates (Source: Solar Payback):

- Design hybrid models with energy efficiency measures and other renewable energy sources (biomass, biogas, heat pumps) in mind;

- Up competitiveness by reducing the cost of technologies and devising new solar heat supply models;

- Develop industrial solutions as ´prosumers`: connect with district heating networks and integrate waste heat recovery;

- Greatly step up communication efforts to raise awareness of SHIP among potential customers in industry;

- Implement measures for raising energy prices (e.g., carbon tax) or stipulating a renewable quota in certain industries.

Websites of organisations and projects mentioned in this article:

IEA SHC Task 49: http://task49.iea-shc.org

AEE INTEC: http://www.aee-intec.at/index.php?lang=en

Fraunhofer ISE: https://www.ise.fraunhofer.de/en.html

Solar Payback: http://www.solrico.com/en/commercial-solar-heat.html

Solar Academy: https://www.iea-shc.org/solar-academy